SPINE

3D Printing Technology for Cage

The anatomical shape of MANTIZ 3D printed cage, with a “bone like surface” guarantees perfect stability and a real interbody fusion solution.

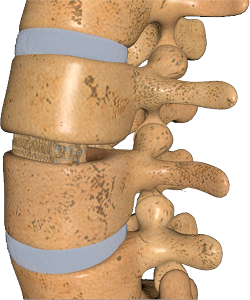

The bone grows inside the cage filling the entire porous structure, the cage can be easily filled with bone substitute to speed up the integration of the implant and the spine fusion.

1. Optimized Bone in Growth

The average porosity of SLM 3D-printed solid parts is 3%, which facilitates accelerated protein and mesenchymal stem cell attachment, providing an optimal environment for bone growth and enhancing the fusion rate.

2. Minimized Subsidence

The MANTIZ 3D-printed cage possesses elasticity similar to that of bone, designed to minimize subsidence by adopting a cross-intersected 3D ring frame mesh.

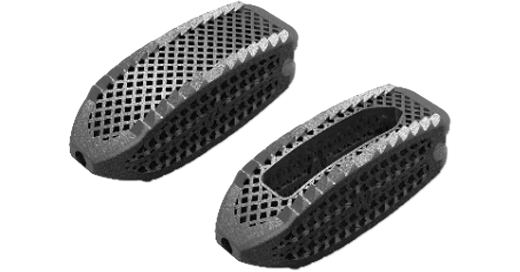

PANTHER-S 3D printed lumbar cage

- Surface properties with excellent cell adhesion function

- Optimized Porous Mesh Structure for Bone Fusion Maximization

- By utilizing ring frame structure with 3D unit structure, human bone-like elastic force is realized

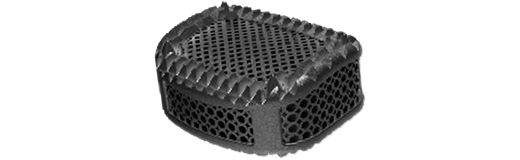

PETRA 3D printed cervical cage

- Surface properties with excellent cell adhesion function

- Optimized Porous Mesh Structure for Bone Fusion Maximization

- By utilizing ring frame structure with 3D unit structure, human bone-like elastic force is realized

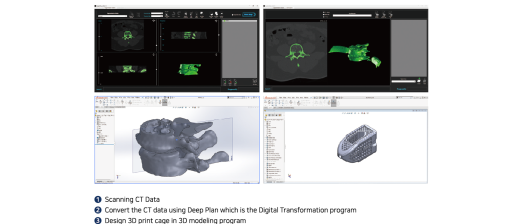

CUSFIT customized 3D printed cage

- Scanning CT Data

- Convert the CT data using Deep Plan which is the Digital Transformation program

- Design 3D print cage in 3D modeling program

KR

KR